|

|

Mignonette Assembly Instructions

NOTE: These are the instructions for Versions 2.1 and 2.0 of Mignonette Game Kit.

If you want to assemble a Version 1.0 Mignonette, the instructions are available

here.

Below are detailed instructions for the assembly of the game kit. These instructions are designed for the beginner, but even if you are an experienced kit builder, we recommend you take a look before proceeding! |

Tools |

Step 01: These are the tools you will need:

http://learn.adafruit.com/minipov3/preparation Mitch wrote a "Soldering Is Easy!" comic book that is a really nice way to learn to solder: http://mightyohm.com/blog/2011/04/soldering-is-easy-comic-book/ |

|

| | ||

Kit parts |

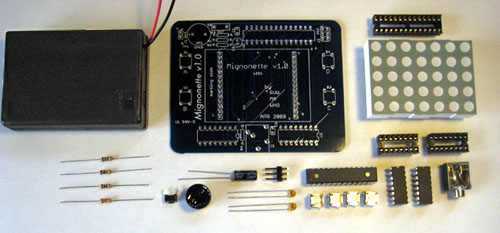

Step 02: Lay out all of the parts before you. All of these parts are available at digikey.com, mouser.com, and jameco.com, except for the LED matrix, which is available at bgmicro.com. A complete list of parts, including suggested parts numbers, are given in our bill of materials (BOM). |

|

| | ||

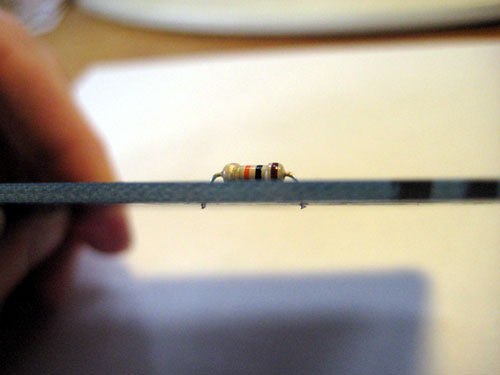

Bending the leads |

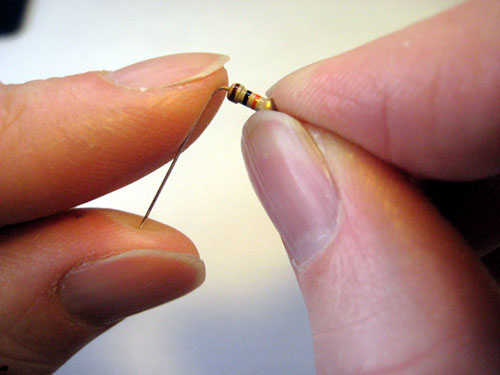

Step 03: We will start with resistor R1. The colored bands are either: brown, black, orange, gold or brown, black, black, red, brown These colored bands indicate the value of the resistor. (10K ohms in this case) The wires of all resistors should be bent down on both sides of the part, as shown. Another word for wires that come out of electronic parts is "leads" (pronounced "leedz"). |

|

| | ||

Insert R1 |

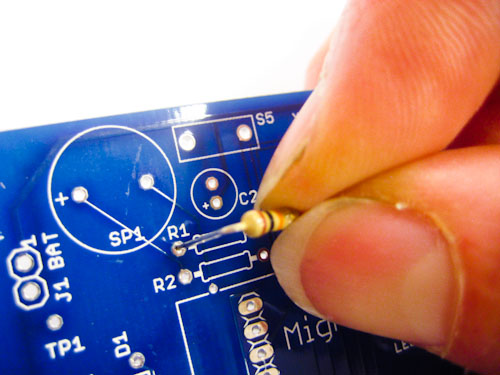

Step 04: Push the leads from R1 into the pads for R1 on the PCB. "PCB" stands for Printed Circuit Board, and is the blue board into which we’ll be soldering all of the electronic parts. "Pads" are the silver parts on the PCB, usually with a hole in the middle, where the parts will be soldered into. It does not matter which lead of a resistor goes into which pad. This is because resistors are "non-polarized". |

|

| | ||

Bending out leads |

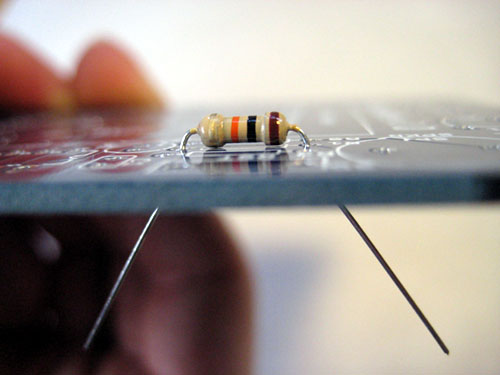

Step 05: After placing R1 through its pads on the PCB, bend its leads outward a little, as shown. This allows the PCB to be turned over without R1 falling out while we solder it in place. |

|

| | ||

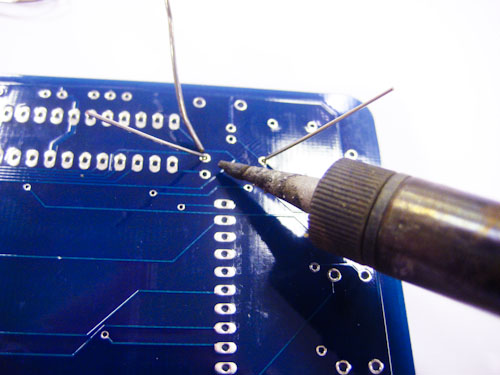

Solder R1 |

Step 06: Solder R1. Soldering is done by following these steps: (For more detailed instructions, please see the link to the "Soldering Is Easy!" comic book under Step 01.)

|

|

| | ||

R1 soldered |

Step 07: Here you can see R1 soldered into place on the PCB. You can tell a nice solder connection by these three qualities:

If you used too much solder then there will be a huge blob of it that shorts out one pad to another pad. If this happens you can heat up the solder blob with your cleaned solder iron tip, hold it there for 2 seconds, and then bang the PCB lightly on the table. This will fling the solder blob to the table, and your solder connection should then be fine. After this you may need to scrape some stray solder off of the PCB with your finger. There is a lot of leeway between not enough solder and too much solder. This is why soldering is easy! |

|

| | ||

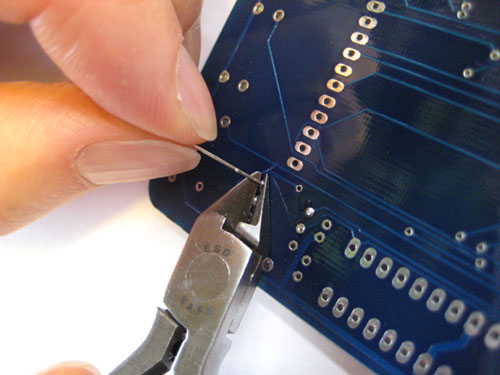

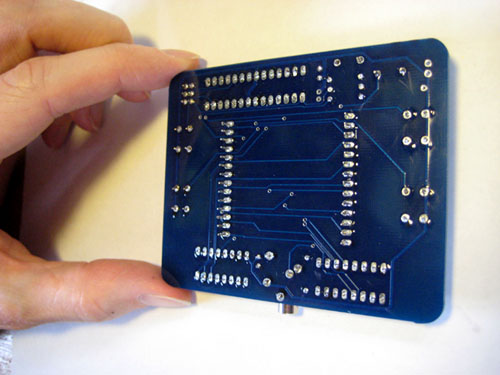

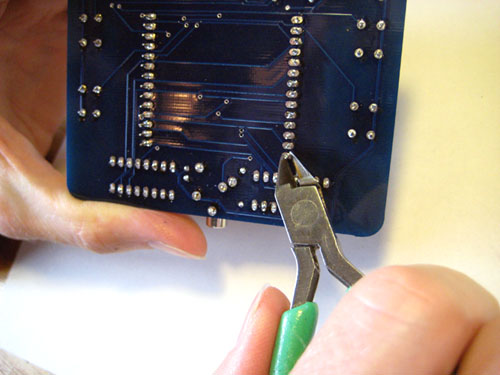

Clipping leads |

Step 08: Clip both of the leads of R1 so that they are somewhat flush with the PCB surface. It is not important that the cut be absolutely flush with the PCB. The main thing is that there is not enough of the lead remaining to bend over and short out to another pad or lead. IMPORTANT: when clipping leads, Always hold the lead with one hand while clipping with the other. This keeps the lead from flying somewhere it is not wanted, such as into your eye, or shorting out some pads somewhere. |

|

| | ||

R1 clipped |

Step 09: You can see here the leads of R1 clipped to an appropriate length. There is no way they can be bent over to short anything out. |

|

| | ||

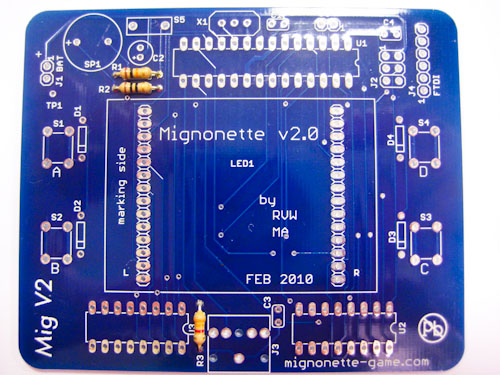

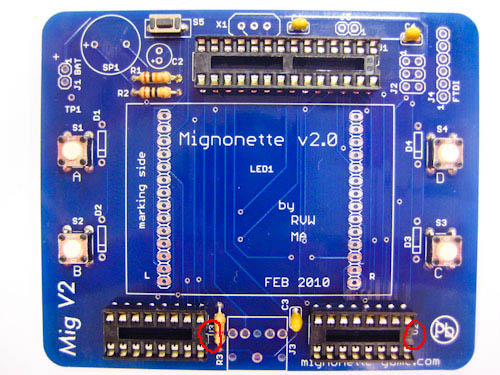

All resistors soldered |

Step 10: Repeat steps 3 through 9 for the other two resistors: R2 and R3. The picture shows where each resistor goes. R2 (10 ohms) has either these colored bands: brown, black, black, gold or these colored bands: brown, black, black, gold, red. R3 (3.3K ohms) has either these colored bands: orange, orange, red, gold or these colored bands: orange, orange, black, brown, red. Remember, resistors are non-polarized, so it does not matter which way they go in their pads. |

|

| | ||

Switches soldered onto PCB |

Step 11: Insert and solder the four game switches into their pads, as shown in the photo. Each switch can be inserted two different ways, and either way is fine. |

|

| | ||

Capacitors C1, C3, and C4 soldered onto PCB |

Step 12: Next we’ll insert and solder capacitors C1, C3, and C4 (C2 comes later). Capacitors come with their leads already bent correctly. Follow steps 4 through 9 for these three capacitors. These capacitors are non-polarized, so it does not matter which way they are soldered to their pads. |

|

| | ||

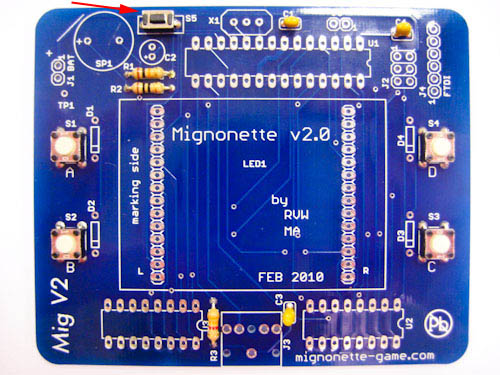

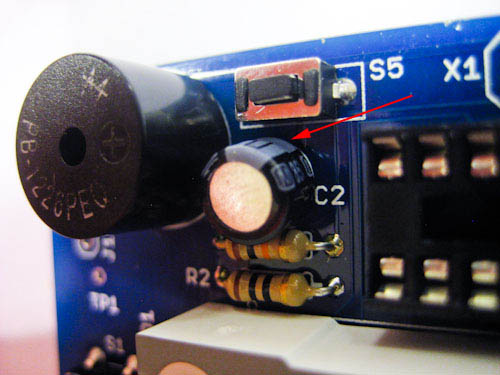

Reset switch soldered onto PCB |

Step 13: Insert and solder the reset switch, S5. It does not matter which way you solder this switch into its pads. |

|

| | ||

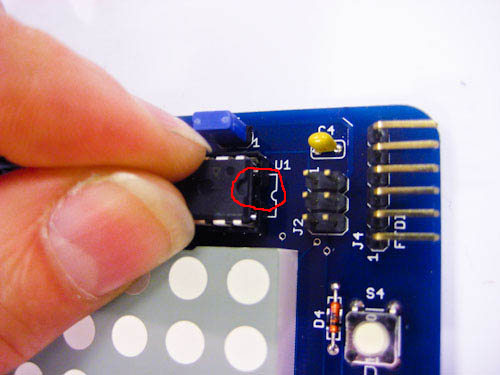

Microcontroller socket placed onto PCB |

Step 14: Insert the socket for U1 into its pads. Notice that there is a notch on the white drawing for U1 that matches with the notch on the socket - make sure these line up when you insert it into the PCB. | |

| | ||

Soldering the microcontroller socket |

Step 15: Solder the two opposite corners of socket U1 into place. Since one hand will be holding the socket and PCB, and the other hand will be holding the solder iron, we do not have a third hand to hold the solder. So, you can use the roll of solder to hold the solder in the correct position, as shown in the photo (bend the solder so that it points down a little bit). If you donít hold the socket in place when you turn the PCB upside down to solder it, it will fall out. So you will need to hold it onto the PCB with one finger, as shown in the photo. Make sure you donít touch the metal on the top of the PCB for the pin you are soldering on the bottom (or you will feel the pain!). After soldering one corner of the socket, solder the opposite corner. |

|

| | ||

Opposite corners of micrcontroller socket soldered |

Step 16: Here you can see two opposite corners of U1 soldered in place. |

|

| | ||

All pads of microcontroller socket soldered |

Step 17: Solder the remaining pins of U1, so that all of its pins are soldered. |

|

| | ||

Driver chip sockets U2 and U3 soldered onto PCB |

Step 18: Position U2 onto the PCB as shown in the photo (be sure to match the notch on the white drawing for U2 with the notch on the socket), and solder it in place by repeating steps 14 through 17. Do the same for U3. |

|

| | ||

AVR programming header soldered onto PCB |

Step 19: Place the AVR programming connector, J2, onto the PCB and solder it in place by repeating steps 15 through 17. For J2 notice that there are long leads on one side and short on the other. Make sure that the short leads are pushed into the PCB. There are two ways to insert J2 into the PCB so that the short leads are pushed into the PCB -- either way is fine. By the way, J2 is not necessary, but if you ever do want to reprogram a new Arduino bootloader into the microcontroller chip, J2 is the connector that is used for this. Pin 1 of this connector is marked on the PCB. "Chip" is another word for Integrated Circuit. |

|

| | ||

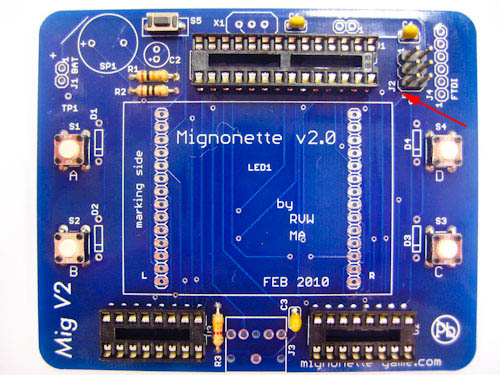

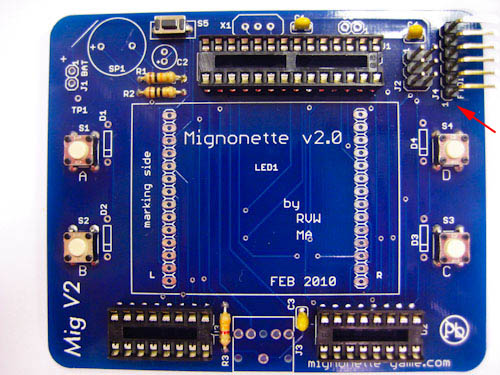

FTDI programming header soldered onto PCB |

Step 20: Place the serial/FTDI programming connector, J4, onto the PCB and solder it in place by repeating steps 15 through 17. Make sure that the short leads are soldered into the PCB, with the long pins facing as shown in the photo. By the way, J4 is the connector that is used to reprogram the game firmware (using an FTDI cable). (You only need to have and use an FTDI cable if you plan on programming new game firmware. Please see the last step on this page for details.) |

|

| | ||

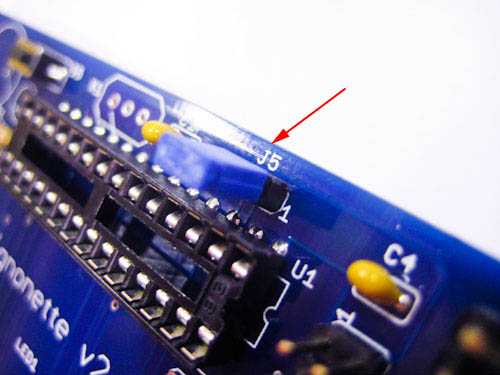

Arduino communications header soldered onto PCB (with jumper) |

Step 21: For J5 notice that there are long leads on one side and short on the other. If it is not already pushed on, push the jumper block onto the long leads of the Arduino communications header. Now place this assembly into, J5 on the PCB. Make sure the short leads of the header are pushed into the PCB, Solder the two leads in place by repeating steps similar to 15 through 17. By the way, J5 is a jumper that can be shorted (or unshorted) with the included jumper block. When you want to play a game, J5 is shorted with the jumper block. If you ever want to program your Mignonette to transmit information to the Arduino software on your computer, then temporarily remove the jumper block (it can be temporarily placed on the J5 header on only one pin so that it doesn’t short the two pins). |

|

| | ||

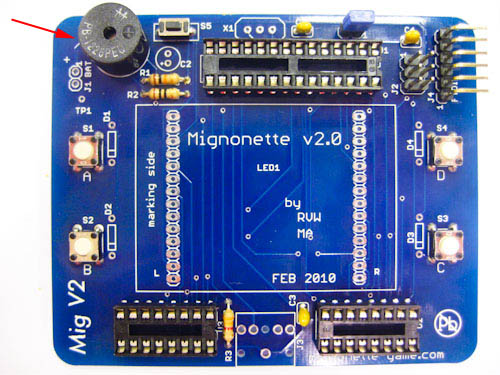

Speaker soldered onto PCB |

Step 22: Place the speaker onto the PCB and solder it. Be sure to cut the excess leads short (and remember to hold the lead while you cut it!). The speaker can be placed into the PCB in two ways, and it does not matter which way you place it (ignore the "+" marking on the PCB). |

|

| | ||

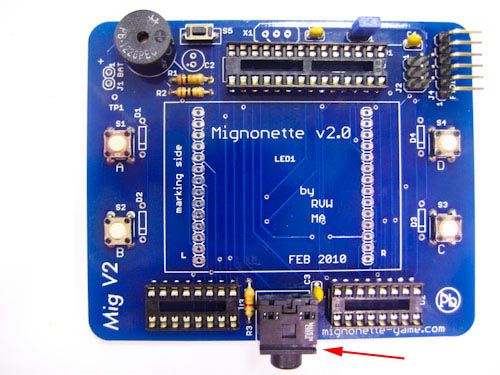

Headphone jack soldered onto PCB |

Step 23: Place the headphone jack, J3, onto the PCB as shown in the photo and solder it. By the way, inserting headphones into J3 turns off the speaker on the Mignonette. The audio quality from the headphones is much better than the sound through the speaker. The Mignonette actually generates high quality 8-bit sound! |

|

| | ||

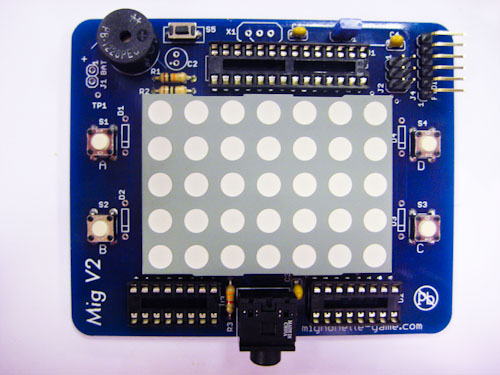

LED matrix placed in PCB |

Step 24: The LED Matrix can be placed into the PCB in two ways, and it does not matter which way you place it. It may be a little tricky to fit all of 28 pins through the 28 pads, since some of the pins may be bent a little. If they are not all lined up, bend the pins a little at a time till they all easily slide through the 28 pads on the PCB (please do not force it). |

|

| | ||

Solder pads on opposite corners of the LED matrix |

Step 25: Solder two opposite corners of the LED Matrix into place by following a similar sequence of steps 15 through 17. |

|

| | ||

LED matrix soldered onto PCB |

Step 26: This photo shows all 28 pins of the LED Matrix soldered into place. |

|

| | ||

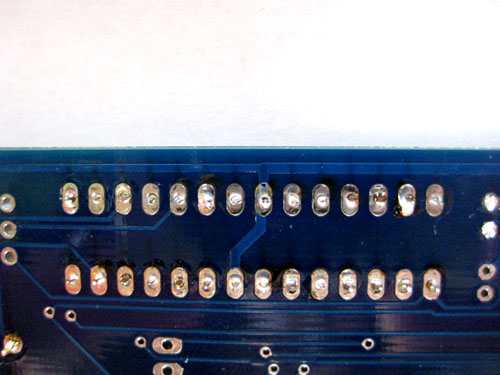

Clipping LED matrix leads |

Step 27: Since the leads from the LED matrix are long enough to bend over and short to each other, clip each lead of the LED Matrix. Do all 28 pins, clipping only one lead at a time. IMPORTANT: remember to always hold the lead with one hand as you clip it with the other. You really do not want any of the leads to go into your eye. Also, these small leads can short out pads on the PCB. Be sure to collect the cut leads and keep them away from the PCB. |

|

| | ||

Diodes D1, D2, D3, and D4 soldered onto PCB |

Step 28: Next weíll insert and solder diodes D1, D2, D3, and D4. Before inserting the parts, bend their leads down similar to the resistors we did earlier. Diodes are polarized, meaning it does matter which way you put their two leads in the two pads. The "-" lead is marked with a black band. Make sure to match the "-" leads of the diodes (with the black bar) with the white bars marked on the PCB, as shown in the photo. Solder in the diodes and clip their leads. |

|

| | ||

Capacitor C2 placed and soldered onto PCB |

Step 29: Place capacitor C2 into its pads in the PCB. Capacitor C2 is polarized, meaning it does matter which way you put its two leads in the two pads. The "-" lead is shorter than the "+" lead. The "-" lead is also marked on the side of the capacitor. Make sure you place the part into its pads with the longer lead put into the pad marked "+". Solder in capacitor C2 and clip its leads. |

|

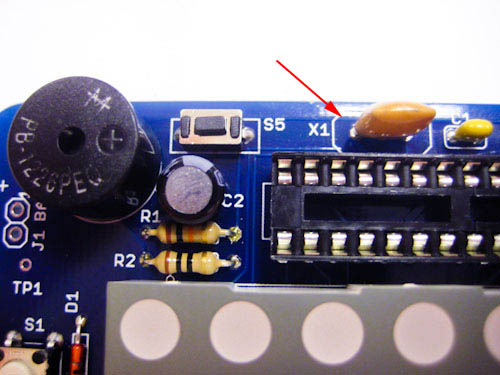

Ceramic resonator soldered onto PCB |

Step 30: Place the ceramic resonator, X1, into its pads in the PCB. It does not matter which way you place this part into the PCB. Solder the three pads of the ceramic resonator and clip the leads. |

|

| | ||

Bending leads on new chips |

Step 31: When chips are new, the leads are often bent outward. Ideally, we want the leads of the chips to point straight down, with all leads parallel to each other. By lightly pushing downward on a table you can make all of the leads parallel. Do this for all three chips. |

|

| | ||

Placing the microcontroller in its socket |

Step 32: Place chip U1 into its socket, making sure that the little notch at one end lines up with the notch in the socket and the PCB, as shown in the photo. Once the pins of the chip are lined up in the socket, push down firmly until the chip is all of the way into its socket. |

|

| | ||

Placing the driver chips in their sockets |

Step 33: Place chips U2 and U3 into their sockets, making sure both of them have their notches lined up with the notches in the sockets and the PCB, as shown in the photo. Once the pins of the chips are lined up in their sockets, push down firmly until the chips are all of the way into their sockets. |

|

| | ||

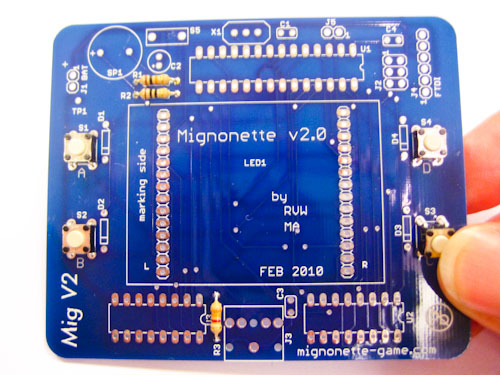

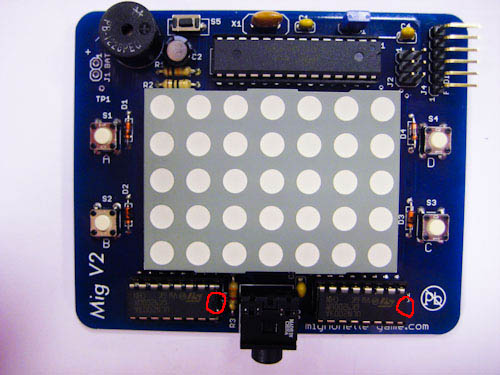

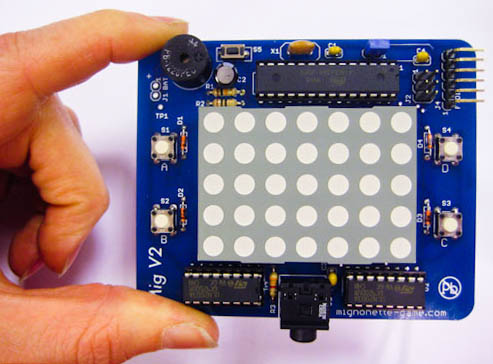

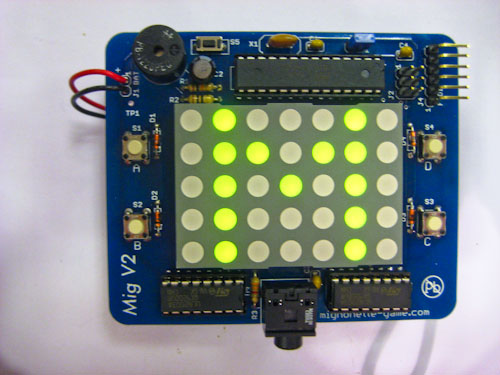

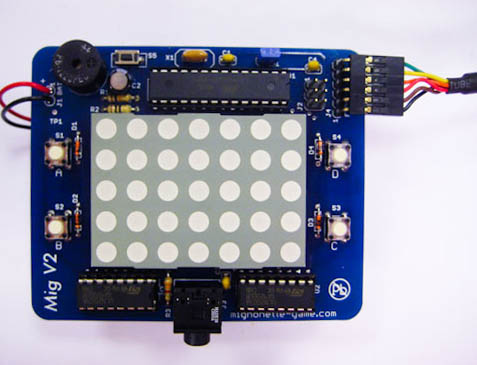

Finished PCB |

Step 34: You are now finished placing and soldering all of the parts into the PCB! This photo shows the end result. |

|

| | ||

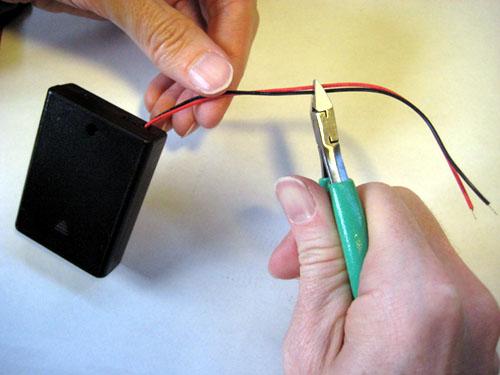

Shorten battery leads |

Step 35: Clip the leads of the battery pack to shorten them. The photo shows about how long to make the wires. The actual length is not critical. |

|

| | ||

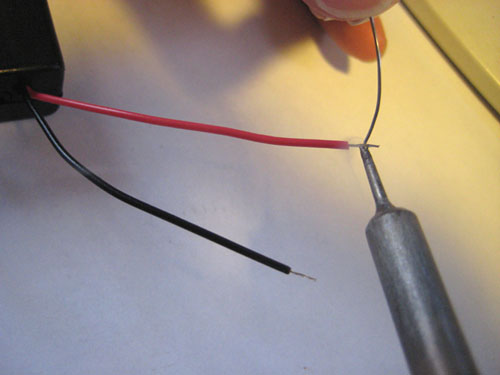

Tin battery leads |

Step 36: Strip about 1/8" (about 3mm) of insulation off of the end of each lead of the battery pack. Then "tin" the exposed wires. Tinning means melting a thin coat of solder onto a lead. This is done to make it easier to solder it to something else (in this case, the pads on the PCB). |

|

| | ||

Solder battery leads to PCB |

Step 37: Solder the two wires of the battery pack into its pads in the PCB, as shown in the photo. The Red wire is "+" and the Black wire is "-"(as is the convention in electronics). |

|

| | ||

Switch on battery pack is OFF |

Step 38: The switch on the battery pack is the On/Off switch for the Mignonette game. For now, turn it to OFF. |

|

| | ||

Insert batteries |

Step 39: Insert three Alkaline AA batteries into the battery pack and replace the battery pack’s cover. You can turn the Power switch on now, and see what happens. If everything is OK, then you should see the Mignonette light up and make sound. If it does not, turn off the power immediately, and debug. Debugging Suggestions:

|

|

| | ||

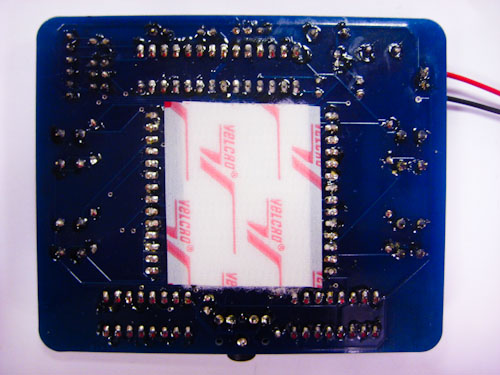

Apply Velcro |

Step 40: In this step we will attach the PCB to the battery pack with the included Velcro strips. When performing this step, please be sure that the PCB is centered over the battery pack, and that the switch on the battery pack is not covered by the PCB. With the two halves of the Velcro strips attached to each other, remove the protective covering from one side of the Velcro (it does not matter which side), and affix it to the back of the PCB, in the middle of the pads for the LED matrix, as shown in the photo. Next remove the protective covering from the other side of the Velcro, and affix it to the battery pack, while making sure that the switch on the battery pack is accessible (and not covered by the PCB). The PCB should be centered over the battery pack. Press firmly on the PCB to allow the glue on the Velcro to take hold. |

|

| | ||

Enjoy! |

Step 41: Enjoy! The Mignonette kit comes pre-programmed with a test program and the Munch game. When power is turned ON, the pre-programmed firmware goes into the test program, which lights up each of the LEDs in the 5x7 matrix in red, with a beep on the speaker, then lights up each of the LEDs green, then lights up the middle LED yellow (which is actually blinking very quickly red and green!). Then you can press each of the four buttons to make sure that they each move the lit up LED around the matrix. If any of the LEDs do not light up, or if any of the buttons do not move the LED, then there is a bad solder connection, so try touching them up (by touching the cleaned solder iron tip to each pad for 1 second). To start your Mignonette into the Munch game, hold down the A button (which is also marked S1) while turning the power to ON. The display will show a green "M" (for Munch) and you will hear a little start-up tune. Then three of the LEDs in the middle of the matrix will light up red (to indicate three lives). The object of Munch is to move the red dot around to eat up the green dots before the yellow dot eats you! Hint: the two buttons on the right move you left and right, and the two buttons on the left only move you up and down if you use them together with the buttons on the right -- tricky and frustrating, but that makes it more fun! There are multiple game levels, and the more you win the more challenging it gets. Best of luck! |

|

| | ||

Program your own games! |

Step 42: Program the microcontroller and enjoy more games! Note: the Mignonette kit comes pre-programmed with a test program and the Munch game, so this step is only needed if you wish to change the game firmware. Now that you see how fun it is to play Munch on your Mignonette, why not program the Mignonette with other games? You can hack your own games by using our game library (which is why we wrote it!). (Alternatively, of course, you could write your own games in C++ or AVR assembly.) You can also download games written by other Mignonette user’s -- please see our Downloads page. To program the Mignonette, you will need an FTDI cable, an FTDI Friend, or equivalent. The black wire side of the FTDI cable connects to the side of J4 marked "BLK" (and the green wire side of the FTDI cable connects to the other side of J4, marked "GRN"). Please see our Programming page for more information about programming the Mignonette. |

|

| | ||